产品中心

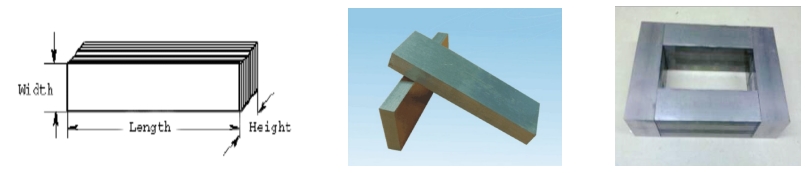

Super Cores are made by stacking iron-based nanocrystalline alloy ribbons or laminations. The laminations are banded together by an adhesive rated for a continuous operating temperature of 155°C or 180°C. The nanocrystalline alloy itself has a higher continuous operating temperature. These forms offer a unique combination of high saturation induction (1.25 T), high permeability, super lower core-loss and near zero noise.

Super Cores can be used in medium frequency (20 kHz~100KHz) and high power (up to 300 kW) PV inverters. These have core losses lower than those of 3% or 6.5% Si steels.

Properties:

Typical ribbon thickness (μm): 20

Density (g/cm3): 7.18

Thermal expansion Coef. (ppm/°C): 7.6

Crystallization temperature (°C): 550

Saturation Induction (T): 1.25

Electrical resistivity (μΩ.•cm): 130

Curie Temperature (°C): 410

Continuous Operating Temperature (°C): 155

Core loss ( @20KHz,300mT): <16 w/kg

Dimensions:

|

MIN (mm) |

MAX ( mm) |

tolerance (mm) |

|

|

L |

20 |

800 |

±1 |

|

W |

10 |

50 |

±0.5 |

|

H |

5 |

85 |

±0.5 |

Specifications:

|

AM-BC- |

Length

|

Width

|

Height

|

Weight (g) |

AM-BC- |

Length

|

Width

|

Height

|

Weight (g) |

|

1 |

90 |

25 |

55 |

790 |

10 |

25 |

25 |

55 |

220 |

|

2 |

100 |

30 |

85 |

1640 |

11 |

30 |

30 |

85 |

490 |

|

3 |

106 |

35 |

85 |

2030 |

12 |

35 |

35 |

85 |

670 |

|

4 |

110 |

30 |

30 |

635 |

13 |

30 |

30 |

25 |

140 |

|

5 |

120 |

40 |

40 |

1240 |

14 |

30 |

40 |

40 |

310 |

|

6 |

135 |

45 |

45 |

1760 |

15 |

35 |

45 |

45 |

455 |

|

7 |

140 |

35 |

36 |

1138 |

16 |

30 |

35 |

36 |

243 |

|

8 |

150 |

50 |

50 |

2420 |

17 |

30 |

50 |

50 |

484 |

|

9 |

155 |

45 |

40 |

1800 |

18 |

35 |

45 |

40 |

406 |

|

10 |

170 |

25 |

25 |

650 |

20 |

300 |

15 |

15 |

415 |

|

11 |

450 |

15 |

15 |

620 |

22 |

800 |

20 |

20 |

1960 |

Stacking factor = 85 ± 3%

Cross-sectional area of the form = W x H x 0.85/100 cm2

Mass of the form = L x W x H x 0.85 x 7.18 / (1000 x 1000) kg

Attention: All the data listed in this catalogue are got from optimum-annealed samples. When these ribbons are made into cores, there may be some variation of the property according to processing technique. All the data here are only for references, but not for guaranty of any order. Cores with other specifications can be provided concerning to customer’s demand.