产品中心

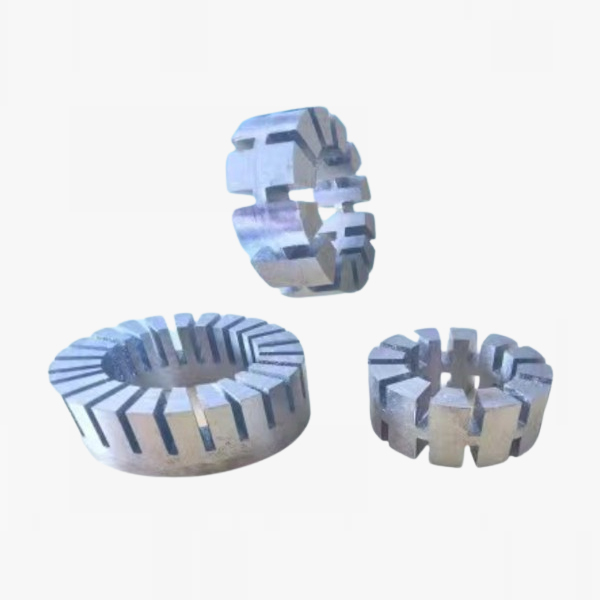

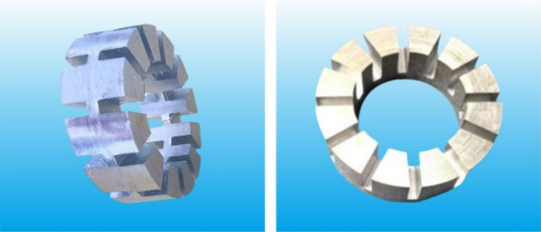

Amorphous stator innovative manufacturing technology (high efficiency, low cost)

With 17 years of experience, Shenzhen AMMET has innovated and developed an amorphous stator manufacturing technology with independent intellectual property rights, which solves the pain point of amorphous material in the stator core that is difficult to process and low efficiency.

Application:

For the future amorphous stator in robot joint motors, low-altitude aircraft, wheel hub motors and other applications to bring a broad prospect.

Performance:

|

Stator core material |

amorphous 1K101 |

Saturation magnetic induction |

1.56T |

|

Curie temperature |

415℃ |

Magnetostriction |

27 ppm |

|

Resistivity |

130 |

Coercivity |

<4A/m |

|

Density |

7.18g/cm3 |

Thickness |

25μm |

|

Lamination |

F >90% |

Iron loss |

Ps <20w/kg @1kHz, 1200mT |

|

Insulation Class |

H |

|

Customized Stator size can currently be made to outer diameter (>40mm ).

|

P/N |

OD |

HT |

Slots |

|

AM-ST-4515-01 |

45 |

15 |

12 |

|

AM-ST-4515-02 |

45 |

15 |

18 |

|

AM-ST-4515-03 |

45 |

15 |

24 |

|

AM-ST-5515-01 |

55 |

15 |

18 |

|

AM-ST-5515-02 |

55 |

15 |

24 |

Attention: All the data listed in this catalogue are got from optimum-annealed samples. When these ribbons are made into cores, there may be some variation of the property according to processing technique. All the data here are only for references, but not for guaranty of any order. Cores with other specifications can be provided concerning to customer’s demand.